20/1/2024 Soufli

During my visit to Soufli, on the 19-21/1/2024, I had the opportunity to learn how to reel raw silk from cocoons in the raw silk reeling unit of Ellias Manaves in Soufli. It was an impressive experience, that I will always remember and which I definitely recommend to anyone.

After all, I was in Soufli, a town immersed in silk tradition, what was I supposed to do on a rainy January afternoon? As they say when in Rome do as the Romans do!

I may know lots about silk and the silkworm but I do not know how to reel raw silk and this was a chance for me to learn.

Reeling silk in this way, gave me an insightful perspective on how silk was reeled in antiquity and why it became such a luxury item. It is a delicate thread that requires skills to master reeling it!

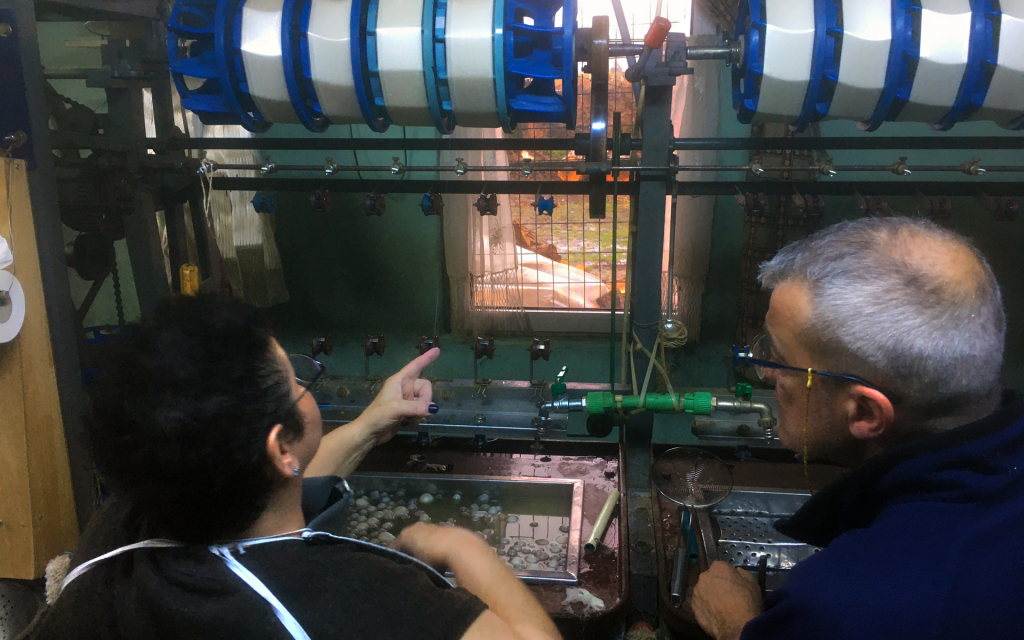

So, during my visit, I asked Pagona (Photo 1) to teach me how to reel raw silk in the machine she uses. The silk thread she was producing on this day was a 25-30 Denier raw silk.

It turns out that it is not as easy as it may look.

First, you boil the cocoons to soften them (Video 1).

Video 1: Brushing cocoon thread ends together in preparation for reeling.

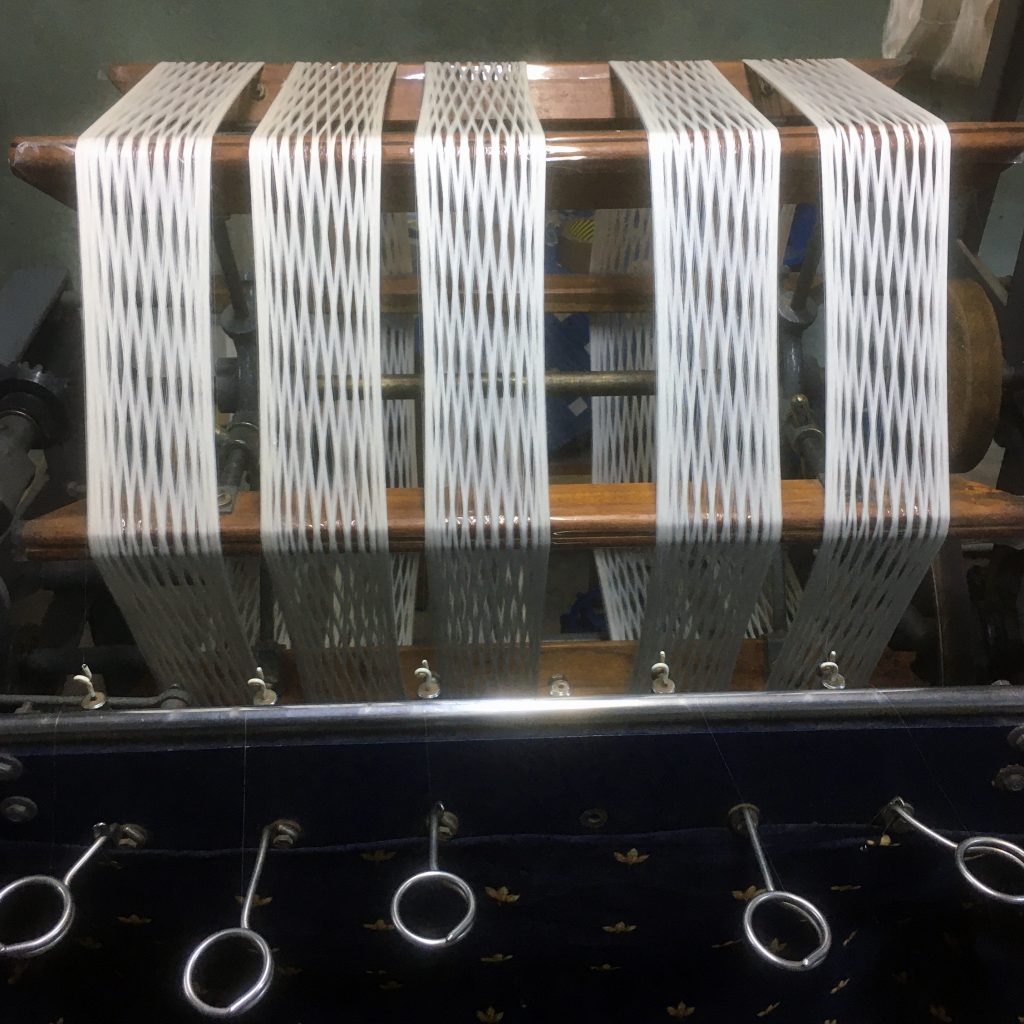

Then you use a brush to catch the edges of the tread from each cocoon (Video 1), then you collect the threads from as many cocoons as you decide to reel together (Video 2) and then you place the thread ends through the machine (Photo 2).

Meanwhile, you hold the other ends of the threads of the other cocoons (Photo 3 and Video 2) in place with your one hand and “feed” each cocoon thread to the reeled threads when one other thread is falling off (Video 3 and Photo 3).

Video 3: Carrying out the reeling of the raw silk thread.

It is painstaking job (Photo 4) that it takes days to learn to do well. Once you learn it, though, as Pagona said it is as easy as knitting. The reeled thread is then placed in the re-reeling wheel before being thrown in a twisting machine. Thrown silk is the twisted silk that is used in weaving.

This raw silk reeling unit is managed by Anne Garcin and produces raw silk that is then made into silk fabrics (see: https://www.metaxana.com/). It is a totally organic and circular economy-based enterprise that is based on Soufli-made raw materials, i.e. the cocoons produced by Ellias Manaves, his wife, Pagona, and their assistant Paschalis , on the same premises. In actual terms, the silkworms are reared on the same building, cocoons are produced and then used for raw silk reeling all under the same roof.

You can see more of the products of this enterprise and buy their products at https://www.metaxana.com. These products are certified locally-made in Soufli. I can assure you of that!